Analyzing Supply Chain Strategy - Case of Indian Pizza Supply Chain

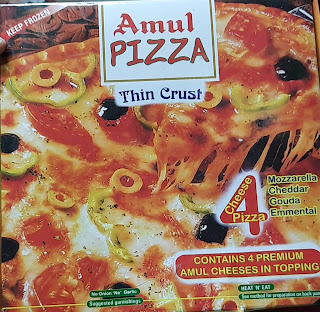

Amul is an exemplary example of a Milk business portfolio. The characteristic of that Supply Chain is predominantly standardized products, variety to a limited extent and more importantly, customers not being demanding about a personalized experience from the product consumption. Supply Chain is tuned to being a Push Supply Chain. A Push Supply Chain Strategy is characterized by standardized SKUs made available in anticipation of demand. The strategy is deployed when the total lead time of Supply Chain is longer than the wait time available with the customer. Amul launched Pizza close to two decades back. Probably the total number of cities where Amul launched Amul Pizza (as a pilot) may have exceeded the total number of operational outlets that closest competitor may have had across the country.This was the scale of launch. Since then Pizza business has come to along way in India. I have met so many people whom I ask this question - Do you know Amul sells Pizza? And ove...